July 2019 Articles:

- THE POTENTIAL FOR NATURAL GAS AS AN ONSITE STORED FUEL

- UNDERSTANDING DEMAND RESPONSE

- ENGINEERING INNOVATION; MANUFACTURING QUALITY

THE POTENTIAL FOR NATURAL GAS AS AN ONSITE STORED FUEL

By Dan Barbersek

Director of Energy Management Solutions, Generac Power Systems

INTRODUCTION

UTILIZING NATURAL GAS

According to research done by Frost & Sullivan, the use of natural gas for onsite power generation has grown 10% in the last ten years. Several driving factors can help explain this growth over the use of diesel fuel include:

- Customer Preference – Environmental concerns both owning and maintaining diesel fuel, as well as emissions concerns and permitting fall squarely upon the end user.

- Diesel Fuel Cost of Ownership – The new low sulfur fuel is more prone to microorganism growth, which has a direct effect on fuel reliability. Strong ongoing maintenance plans and fuel polishing systems’ cost or fuel replacement programs must be accounted for.

- Fuel Delivery – When a major event strikes, such as hurricanes and flooding, getting diesel fuel delivered over damaged roads can be a major hurdle to overcome as well as supply and demand constraints.

The use of natural gas bypasses these three major challenges, but it comes with other considerations. Delivery reliability is commonly a concern when it comes to natural gas. This comes even though the performance of our natural gas delivery system in the United States has far outperformed the electrical grid year after year. MIT Lincoln Laboratory conducted one of the more comprehensive studies, “Interdependence of the Electricity Generation System and the Natural Gas System and Implications for Energy Security”, in May 2013 to support this claim. This study concluded that the natural gas distribution system operates at a reliability of over 99.999%. On top of this, natural gas will flow if all electric utilities shut down for several months. The study said this is due to several factors; one being that many of the natural gas compressor stations run off natural gas, and the total volume of gas piping (4 trillion cubic feet) currently in the system.

Even with strong delivery systems, the use of natural gas becomes limited especially when it comes to generators that are supporting life safety loads. Both the NFPA, and the NEC within the NFPA, reference the requirement of on-site fuel as well as site approval from local Authority Having Jurisdiction (AHJ) to utilize this fuel for life safety applications.

NATURAL GAS STORAGE

Due to the activity of the transportation sector, natural gas storage technology is experiencing tremendous growth.

Compressed Natural Gas (CNG)

CNG storage for industrial applications dates back to the 1940s. The approach is currently favored by the transportation industry. CNG is generally stored in high-pressure cylinders, typically at 3,600 lb/in2 for mobile applications. At 3,600 lb2, the volume of natural gas is reduced by a factor of 296 compared to atmospheric pressure; or a storage efficiency of 296 V/V. The V/V ratio represents the volume gas at standard temperature and pressure compared to the storage volume. Type I cylinders are the most common for CNG and are made of steel. These cylinders are susceptible to corrosion if the moisture level of the gas is high. Due to their high pressure, their size, shape and material are very limited.

Absorbed Natural Gas (ANG)

Adsorption storage is based on the properties of natural gas referred to as the ads=orbate and the adsorbent, which is typically a carbon, graphene or metal-oxide. These properties give the adsorbent the ability to store the gas ten to hundreds of times the amount of gas given the volume and pressure compared to CNG. The ultimate goal of ANG technology is to safely store natural gas in the minimum volume at a pressure not exceeding 500 lb/in2. Filling the tanks does need to be examined. If the “fast fill” (5-10 minutes) method is used, the heat that is caused utilizing this method must be managed. When looking at using this technology for an Emergency Power System (EPS), these concerns are diminished. This is due to how these tanks will be utilized in this type of application. Once the tanks are initially filled, and will stay that way for long periods, they will not need to be filled again until the following two simultaneous conditions are met, loss of utility and loss of the natural gas supply.

Breaking down the numbers for these conditions looks like the following (assuming the utility has a 99% availability and the natural gas has a 99.9% availability.

P (Natural Gas Supply Fail/Utility Power Fail) = 0.0001 x 0.01 = 0.00001

This will give the EPS of 99.999% availability that either the utility or the natural gas will be present during an event to run. It is also important to remember that the loss of utility will have no bearing on these tanks, only when both utility and natural gas are lost.

Cost

Cost on EPS is driven directly by kW size so for this costing example we will assume a 500kW natural gas generator with a two hour back up supply requirement. Using the CNG approach with high-pressurized cylinders will cost around $33,000. A standard UL 142 double wall diesel fuel tank (1000 Gal) will cost about $21,500. Currently, there are no manufacturers that make ANG tanks for this size as this technology is coming out of the vehicle market, but today’s cost comparisons are coming in at around ~$150/CF. Their target goal to make this technology a viable solution would be to get this manufacturing cost down to $55/CF. (Please note that these costs do not reflect the natural gas compressor)

Codes

NFPA 52 is restricted to vehicle fuel systems, their associated fueling and gas storage systems. It is not intended to cover stationary equipment such as emergency generators. NFPA 55 does provide guidance for CNG or ANG storage systems as applied to an EPS but it may be helpful until other codes and standards adapt. NFPA 54 – which encompasses the National Fuel Gas Code, does not directly address CNG or ANG systems. Paragraph 1.1.1.2 specifically exclude gas generators and compressors. Some requirements will affect the use of ANG as an on-site stored fuel. In addition, paragraph 5.3.2.1 does reference interconnections for standby gas. Therefore, as this technology goes, the codes will have to adapt to this growth.

End Game – Reliability

While there are many positive reasons for using natural gas for on-site power generation, the key and most important factor is overall system reliability. For many years, this meant diesel-powered generators with onsite diesel fuel storage tanks, but diesel fuel grade (low Sulfur) requirements and disaster frequency and severity continues to challenge this statement. Region history must be thoroughly examined along with education and knowledge regarding incoming technologies.

UNDERSTANDING DEMAND RESPONSE

By Dan Barbersek

Director of Energy Management Solutions, Generac Power Systems

INTRODUCTION

The phrase “Demand Response”, or DR, can have many different meanings, as well as many different approaches to achieve this request. With this being said, demand response has one main focus, and that is to reduce the load. The action can have several results, being either grid reliability or financial gain. This paper will explain these definitions and approaches.

GRID SUPPORT

DR programs, when driven by the local utility companies, can be summed up simply as “Grid Support”. This is where either by development planning or un-expedited growth, there are areas within the utility distribution system where customers could experience un-stable delivery of electricity. This can be a localized event or an entire distribution event. The challenge for the local utility is that some of these load levels are not always present. An example of this would be during a hot summer day when all of the air handlers turn on, this now causes an increase in this customers load levels. The challenge for the utility company is they can approach this two different ways. The first approach is they can build up power generation along with transmission capabilities to be able to support these loads. This, of course, is not easily achieved, permitting, right of way challenges can extend construction timelines and capital equipment comes at a great expense. The alternative to this approach is to have customers reduce, or just turn off, their loads.

REVENUE DRIVEN

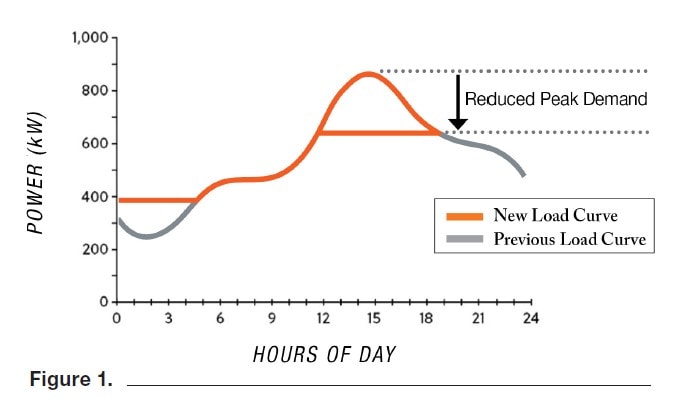

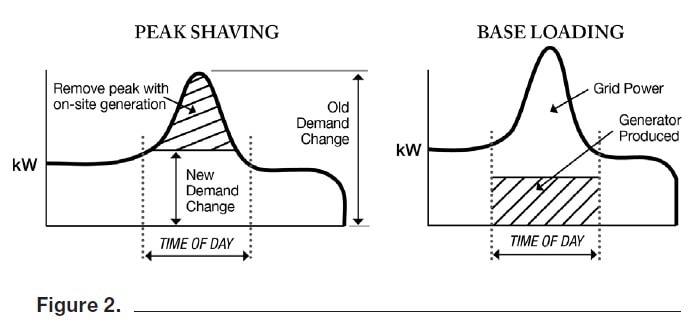

Revenue driven demand response can be used several different ways. One would be peak shaving (see figure 1). This shows that a control system is constantly monitoring the client’s load levels. When the load starts to approach a load shed trigger, then a DR action is put into play. This could be anything that will reduce the load, like shutting down equipment and/or turning on local on-site generation.This action is solely triggered by site conditions and power requirements. These types of applications tend not to have long operation hours, typically 200 hours or less annually, and can be very sporadic depending on changing site conditions.

HOW TO ACHIEVE DEMAND RESPONSE

There are several ways to achieve DR, either customer or utility driven. One of the easiest approaches is to just shed or turn off loads. The issue, however, is if the customer can operate without the equipment that is running at the time. It can be a very daunting task to find the right circuit breakers and to have the on-site personnel capable of performing this task both during and after the load shedding event.

A more secure approach is to utilize on-site generation. This can be accomplished by turning on the on-site generator and transferring the building load onto the generator which will result in load reduction. Having this on-site power generation for emergency back-up provides great benefits. Besides the most important benefit of life safety, this feature can keep daily operations going as to not affect the bottom line, as well as a place of refuge. Of course this comes at a cost, with the option of having DR these costs can be off-set, or in some cases actually achieve a true return on investment.

WHAT KIND OF GENERATORS CAN BE USED?

The EPA has very strict rules when it comes to running on-site generators when there is not an actual electrical outage at the site. If the generator is connected to a diesel engine, the engine must have a Tier 4 emissions rating. Tier 4 rated engines are 30% – 40% more expensive than everyday diesel engines. Tier 4 engines are only required when the units are either mobile or they are being used during non-emergency events. If the generator is connected to a natural gas engine, that engine generator must be labeled for non-emergency use. This labeling should come from the OEM. If the unit is labeled for emergency use the unit can be site certified, but this will have to be done every three years and becomes the sole responsibility of the end-user.

With careful planning demand respond has many different benefits including financially and increased system reliability.

ENGINEERING INNOVATION; MANUFACTURING QUALITY

Generac Industrial Power designs, engineers, and manufactures our products in Wisconsin, United States. From start to finish, we have the hardest working team in the business, making sure you have the best available product on the market. We take pride in the details and every step of the process is completed with the customer in mind. Our team designs market leading innovations and builds each part, making sure it works when you need it most.

DESIGN

Our design engineers study, research and develop ideas for new products and the systems that produce them. We are not only concerned with making products that look good and are easy and safe to use, we are also concerned with ensuring products can be made cost-effectively and efficiently.

Typical Tasks for a Generac Design Engineer:

- Brainstorm possible power solutions

- Research design effectiveness and cost-efficiency for the customer

- Assess the usability, environmental impact and safety of the possible solution

- Use computer-aided design (CAD) and computer-assisted engineering (CAE) software to create prototypes

- Collect and analyze data from prototypes

- Modify designs and retest

When designing generator systems, engineers must ensure the generators and the building’s electrical systems they support are appropriate for the application.

Many questions must be addressed before starting the generator system design. Most of these questions are related to the application and the site operating conditions, which drives the selection of the different generator system components and their characteristics.

Design Considerations:

- Code compliant

- Location of generator system

- Load types and electrical characteristics

- Engine-generator system

- Transfer switches

- Paralleling

- Generator sizing